DIFFERENCES BETWEEN TURBOCHARGER AND SUPERCHARGER

Let's start with the similarities. Both turbochargers and superchargers are called forced induction systems. They compress the air flowing into the engine (see How Car Engines Work for a description of airflow in a normal engine). The advantage of compressing the air is that it lets the engine stuff more air into a cylinder. More air means that more fuel can be stuffed in, too, so you get more power from each explosion in each cylinder. A turbo/supercharged engine produces more power overall than the same engine without the charging.

The typical boost provided by either a turbocharger or a supercharger is 6 to 8 pounds per square inch (psi). Since normal atmospheric pressure is 14.7 psi at sea level , you can see that you are getting about 50-percent more air into the engine. Therefore, you would expect to get 50-percent more power. It's not perfectly efficient, though, so you might get a 30-percent to 40-percent improvement instead.

The key difference between a turbocharger and a supercharger is its power supply. Something has to supply the power to run the air compressor. In a supercharger, there is a belt that connects directly to the engine. It gets its power the same way that the water pump or alternator does. A turbocharger, on the other hand, gets its power from the exhaust stream. The exhaust runs through a turbine , which in turn spins the compressor (see How Gas Turbine Engines Work for details).

There are tradeoffs in both systems. In theory, a turbocharger is more efficient because it is using the "wasted" energy in the exhaust stream for its power source. On the other hand, a turbocharger causes some amount of back pressure in the exhaust system and tends to provide less boost until the engine is running at higher RPMs. Superchargers are easier to install but tend to be more expensive

TURBOCHARGER

How Does a Turbocharger Work?

You've heard the word "turbo" tossed around a lot, especially by performance car enthusiasts. But all you know is that it means an engine has more "oomph" to it than normal. But what exactly is going on underneath that hood? Let's open it up and take a look.

It's All About Better Combustion

Before you can truly appreciate what a turbocharger does for an engine, you need to understand the basics of internal combustion.

Internal combustion engines are "breathing" engines. That is to say, they draw in air and fuel for energy. This energy is realized as power when the air-fuel mixture is ignited. Afterward, the waste created by the combustion is expelled. All of this is typically accomplished in four strokes of the pistons.

Internal combustion engines are "breathing" engines. That is to say, they draw in air and fuel for energy. This energy is realized as power when the air-fuel mixture is ignited. Afterward, the waste created by the combustion is expelled. All of this is typically accomplished in four strokes of the pistons.

What a turbocharger does is to make the air-fuel mixture more combustible by fitting more air into the engine's chambers which, in turn, creates more power and torque when the piston is forced downward by the resulting explosion. It accomplishes this task by condensing, or compressing, the air molecules so that the air the engine draws in is denser. Now, how it does that is the real story here.

A Tale Of Two Wheels

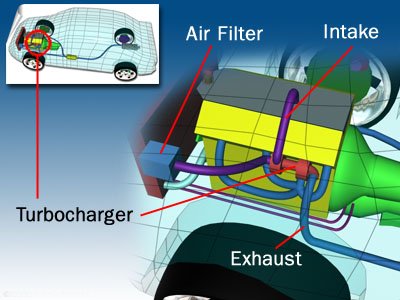

A turbocharger is basically an air pump. Hot exhaust gases leaving the engine after combustion are routed directly to the turbine wheel side of the turbocharger to make it rotate. That turbine wheel is connected by a shaft to a compressor wheel. As the turbine wheel spins faster and faster, it causes the compressor wheel to also spin quickly. The rotation of the compressor wheel pulls in ambient air and compresses it before pumping it into the engine's chambers.

As you may have guessed, the compressed air leaving the compressor wheel housing is very hot as a result of both compression and friction. So what's needed is a way to cool that air down before it enters the chambers. That's where a charge-air cooler (or "heat exchanger") comes in. It reduces the temperature of the compressed air so that it is denser when it enters the chamber (heat causes things to expand, as we all learned in science class). The charge-air cooler also helps to keep the temperature down in the combustion chamber. All together, the engine, turbocharger and charge-air cooler form what is known as a "charge-air system".

Some systems also include a tip turbine fan which draws air across the charge-air cooler to further reduce the temperature of the compressed air generated by the turbocharger.

Not As Easy As It Looks

The basic principal behind turbocharging is fairly simple, but a turbocharger is a very complex piece of machinery. Not only must the components within the turbocharger itself be precisely coordinated, but the turbocharger and the engine it services must also be exactly matched. If they're not, engine inefficiency and even damage can be the results. That's why it's important to follow correct installation, operating and preventative maintenance procedures.

Supercharging

What is Supercharging?

A supercharger forces air into the combustion chamber to provide more oxygen to provide better combustion. They are like air compressors and come in many different configurations.

How they work

Supercharges usually run off of a pulley that is connected to the engine like the alternator or power steering pump. They force the air into the combustion chamber by compressing the air via a turbine or screws.Types of Superchargers

There are 2 main types of Superchargers, Positive Displacement and Dynamic Compressors.Positive Displacement

Positive Displacement superchargers produce a fixed amount of pressure that doesn't increase much as the engine increases RPM's. That means the added benefit decreases at higher RPM's.Roots

The Roots Supercharger (or Blower) uses a pair of meshing lobes. They trap air in pockets surrounding the lobes and then the air is forced from the intake side of the supercharger to the exhaust side.The Roots Supercharger was patented in the 1860's by the brothers Francis Marion and Philander Roots of India.

Lysholm Screw

The Lysholm Screw aka Twin Screw Supercharger works by pulling air through a set of counter rotating screws that resemble worm gears. These screws are high tolerance and have low leak levels compared to the Roots-Type superchargers.Lysholm Supercharges are named after Alf Lyshom whom invented them.

Scroll-Type or G-Lader

Dynamic Compressors

Unlike the Positive Displacement superchargers that produce an almost fixed pressure output at any RPM, the Dynamic Compressors produce more pressure as the RPM's increase.Centrifugal

The Centrifugal Supercharger is basically half of a Turbo charger. The exhaust turbine is replaced with a belt, gear system or chain to drive the compressor. These superchargers are considered to be the most efficient but doesn't' produce boost a low RPM's.

Axial Flow

Axial Flow Compressors work much like Jet Engines. They have several fan blades that compress the air in stages inside the housing. These compressors have a much lower outlet air temperature than other compressor types.